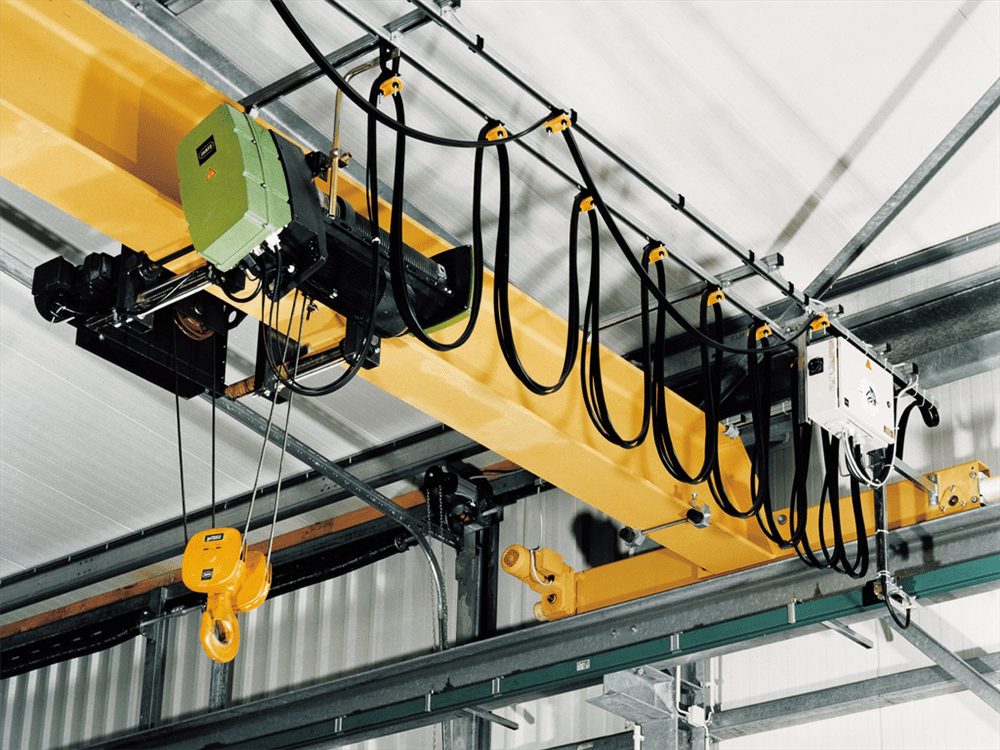

MONORAIL GANTRY CRANES

Monorail Bridge Cranes, which have forward and reverse movement capability, are work machines used for lifting and transporting materials. These work machines have two different speed modes. A monorail bridge crane operating in normal speed mode can generally be used in many applications. In addition, slow transport mode is required for some materials. Slow transport mode is preferred for such sensitive products. The fact that monorail gantry cranes have two different operating modes creates convenience during the execution of the work. In this way, process control can be done without interruption.

This type of cranes can be used to transport products of different weights from one tonne to twenty-five tonnes. Monorail bridge cranes, which are among the construction machines that can be used in various industrial branches, create advantages in terms of labour force thanks to their technical features.

TECHNICAL SPECIFICATIONS OF MONORAIL GANTRY CRANES

Technical Specifications of Monorail Bridge Cranes facilitate their use in many different areas. The usage areas of these products include mechanical production workshops, product assembly lines, storage areas, cargo areas.

During the control of such work machines, manual control can be used or remote control systems can be used. Thanks to monorail bridge cranes, minimum hook movement can be achieved.

In addition, minimum hook dimensions and approach distance are created. These work machines, which minimise the conditions for wear and tear, also stand out with their low maintenance costs. When analysed in terms of investment cost, its low cost is among the reasons why it is preferred.

Monorail gantry cranes are easily used in facilities with low headroom.

These work machines are preferred if the facilities have short axis spans.

They are reliable tools in stacking operations as well as transport operations.

It is economically advantageous in transport and stacking.

Monorail bridge systems have low investment costs.

It makes soft take-off thanks to special production motor and reducer groups.

The impact-free operation system results from the special production of the gearbox group. This also ensures the long life of the work machine.

The cranes can be controlled by push buttons with the ability to move along the beam or by remote control.

Crane tracks can be connected to the roof truss in bottom-suspended monorails. In this way, more lifting height can be obtained.

It provides convenience in terms of assembly.

The basic load effect on the building is less.

Rolled profile beams can be used up to 18m axis spans.

For axis spans over 18 metres, box beams are used.